Top Trends in Battery Testing Equipment for Lithium-Ion Applications

Table of contents:

Innovations from Leading Battery Test Equipment Manufacturers

How New Testing Tools Improve Lithium Battery Pack Efficiency

Market Insights What Procurement Teams Should Watch in 2025

Innovations from Leading Battery Test Equipment Manufacturers

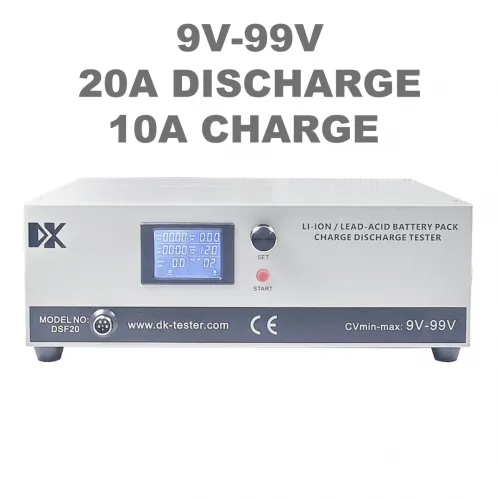

The latest developments in battery test equipment focus on accuracy, automation, and scalability. Manufacturers are producing sophisticated lithium battery testers and solutions that integrate intelligent technologies like AI and IoT. Tools such as the DSF20 Charge-Discharge Tester, widely used for lead-acid and lithium battery testing, underscore the trend toward modular designs. This type of machine offers high precision capabilities over a broad voltage range (9V to 99V), supporting both charging and discharging procedures efficiently. Enhanced features such as automated operations, real-time data sampling, multi-device management via software, and extensive data analysis functionality ensure ease of use, reliability, and consistency. Suppliers now strive to meet growing quality demands by emphasizing features such as reverse polarity protection, customizable parameters, and seamless online operation methods.

How New Testing Tools Improve Lithium Battery Pack Efficiency

Efficiency remains a key driver in the innovation of lithium-ion battery testing equipment. With the increased complexity of battery chemistries and battery pack designs, modern testers are aimed at optimizing workflows and reducing downtime during the testing process. For instance, high-capacity testers now provide detailed charging and discharging curves, enabling insights into battery aging while enhancing predictability for battery lifecycles. Additionally, supporting tools maximize operational convenience by offering users the ability to remotely set or monitor testing conditions. These solutions are critical in applications such as EV battery manufacturing, where battery packs must adhere to the highest safety and durability standards. Modules designed to measure real-time voltage, current, and temperature variations allow engineers to identify issues quickly, reducing wasted energy and elongating battery lifespans. Furthermore, advancements in software integration now allow seamless data analysis and reporting, helping manufacturers identify trends and improve overall production quality. These innovations not only ensure precise testing but also accelerate the transition to more sustainable energy solutions.

Market Insights What Procurement Teams Should Watch in 2025

By 2025, procurement teams will need to focus on several emerging factors when considering battery testing equipment suppliers. First, understanding advancements in software integration will be pivotal. Many battery testers now come with companion software capable of communicating over LAN networks, simplifying management and enabling comprehensive data collection and analysis. Next, scalability will be non-negotiable, as industries like EVs require tools that adapt to testing needs for larger and more complex battery systems. Lastly, sustainability will play a bigger role in procurement decisions. Testers designed with eco-friendly materials or energy-efficient operations will meet increasingly stringent environmental regulations while offering a competitive advantage. Companies that align themselves with innovative suppliers who adopt cutting-edge technologies will be better positioned to lead the shift toward clean energy solutions.

Modern battery test equipment represents a significant leap forward in both technology and capabilities, offering advanced solutions for a variety of industries. Whether you are testing small lithium-ion batteries for consumer electronics or large EV battery packs for electric vehicles, these tools are designed to meet the increasingly complex demands of today’s energy storage systems. By selecting the right testing equipment, businesses can not only enhance efficiency but also ensure higher-quality outcomes, reduce downtime, and optimize overall productivity. With the growing focus on renewable energy and electric mobility, having reliable and precise testing tools has never been more critical for staying competitive in the market.

Comments

Post a Comment