Exploring the Benefits of Tungsten Carbide Composite Rods in Tooling

Table of content:

Top Reasons to Choose Tungsten Carbide Rods for Tooling Applications

Industry Secrets: Finding the Best Tungsten Carbide Rods Suppliers

How Tungsten Carbide Rods Manufacturers are Innovating the Tooling Industry

Maximizing ROI with Tungsten Carbide Composite Rods

Top Reasons to Choose Tungsten Carbide Rods for Tooling Applications

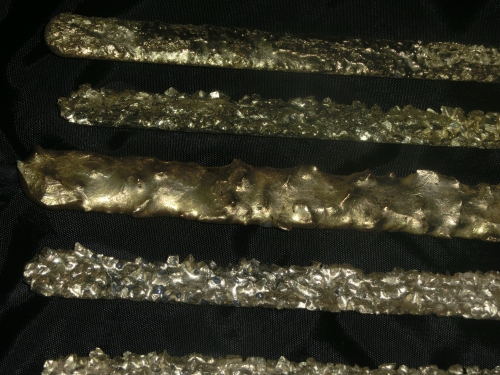

Tungsten carbide rods are renowned for their toughness and versatility, making them ideal for tooling applications. These rods offer superior wear resistance, which is crucial for tools that undergo constant use and friction. The unique composition of tungsten carbide ensures that the rods maintain their integrity even under extreme conditions, reducing the need for frequent replacements and maintenance. This durability translates into cost savings and increased productivity for businesses. Additionally, tungsten carbide rods are highly adaptable, allowing for customization to meet specific industrial needs. Whether you require rods for drilling, cutting, or grinding, tungsten carbide rods provide the strength and precision necessary for optimal performance. By choosing these rods, industries can achieve higher efficiency and reliability in their operations.

Industry Secrets: Finding the Best Tungsten Carbide Rods Suppliers

Identifying reliable tungsten carbide rods suppliers is crucial for ensuring the quality and performance of your tooling equipment. The best suppliers offer a wide range of products that cater to various industrial needs, providing solutions that enhance productivity and longevity. When selecting a supplier, it is essential to consider their reputation, experience, and the quality of their products. A well-established supplier will have a proven track record of delivering high-quality tungsten carbide rods that meet stringent industry standards. Additionally, they should provide excellent customer support and technical assistance to help you make informed decisions. By partnering with reputable tungsten carbide rods suppliers, businesses can ensure they receive products that offer exceptional performance and durability, contributing to the overall success of their operations.

How Tungsten Carbide Rods Manufacturers are Innovating the Tooling Industry

The role of tungsten carbide rods manufacturers in advancing the tooling industry cannot be overstated. These manufacturers are at the forefront of innovation, continually developing new techniques to enhance the properties and applications of tungsten carbide rods. By investing in research and development, manufacturers are able to produce rods that offer improved wear resistance, toughness, and precision. This innovation is driven by the need to meet the evolving demands of various industries, ensuring that tungsten carbide rods remain a vital component in modern tooling. Manufacturers are also focusing on sustainable practices, reducing the environmental impact of production processes while maintaining high standards of quality. By choosing products from leading tungsten carbide rods manufacturers, businesses can benefit from cutting-edge solutions that enhance their operational efficiency and sustainability.

Maximizing ROI with Tungsten Carbide Composite Rods

Investing in tungsten carbide composite rods can lead to significant returns on investment for businesses. These rods are designed to withstand the rigors of intensive use, reducing the need for frequent replacements and minimizing downtime. The exceptional durability and performance of tungsten carbide composite rods ensure that tools remain effective and reliable, even in challenging environments. This reliability translates into increased productivity and cost savings, as businesses can focus on their core operations without worrying about tool failures. Furthermore, the ability to customize tungsten carbide composite rods to meet specific industrial requirements adds value, allowing businesses to achieve optimal results in their applications. By leveraging the benefits of tungsten carbide composite rods, companies can enhance their tooling processes and maximize their ROI.

In conclusion, the use of tungsten carbide composite rods in tooling applications offers numerous advantages, from improved durability to enhanced performance. By understanding the benefits and choosing the right suppliers and manufacturers, businesses can optimize their operations and achieve greater efficiency. As the tooling industry continues to evolve, the demand for high-quality tungsten carbide rods remains strong, making them a crucial component in achieving success. Whether you are looking to improve your current processes or explore new applications, tungsten carbide composite rods provide the reliability and performance necessary for modern industrial needs.

Comments

Post a Comment