The Future of Manufacturing: Tube Filling and Sealing Machines

Table of contents:

Innovations in Tube Filling Machine Design and Functionality

Why Choose a Tube Filling Machine Manufacturer with Experience

The Role of Automatic Tube Filling Machines in Modern Industries

Comparing Tube Filling and Sealing Machine Options for Businesses

Innovations in Tube Filling Machine Design and Functionality

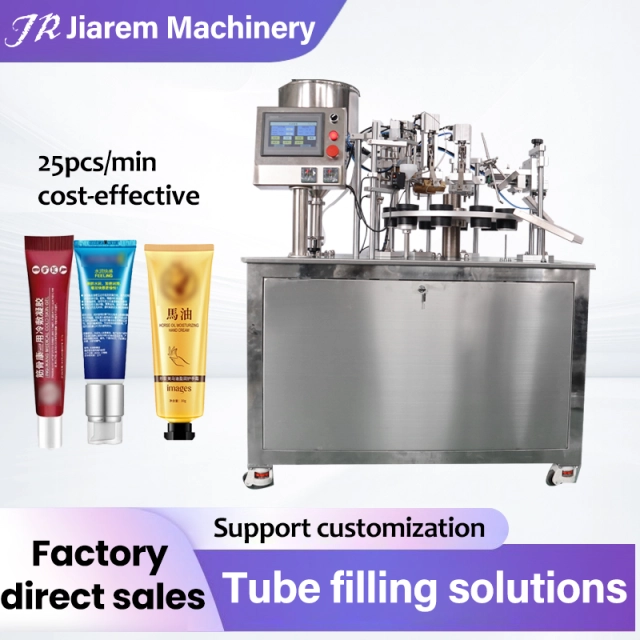

The tube filling and sealing machine industry has witnessed remarkable advancements in design and functionality. Modern machines, such as those offered by leading tube filling machine manufacturers, incorporate features like manual intubation to the turntable and automatic filling. They utilize an internal heating filling method to seal the tube's tail, followed by clamping and cutting off excess material. These innovations not only enhance the sealing process but also ensure product integrity. Furthermore, the incorporation of user-friendly operation panels, leakage prevention features, and customizable production dates reflect the industry's commitment to meeting diverse business needs. Such innovations are vital in maintaining the competitive edge of a tube filling machine supplier in the global market.

Why Choose a Tube Filling Machine Manufacturer with Experience

Selecting an experienced tube filling machine manufacturer is crucial for businesses aiming to optimize their production lines. Established manufacturers bring a wealth of knowledge and expertise, ensuring that their machines meet high standards of quality and reliability. Companies like Guangzhou Jiren Automation Equipment Co., LTD offer a broad range of products and services, including customization options to cater to specific business requirements. Their extensive experience in the industry guarantees not only the quality of the machines but also comprehensive support services such as after-sales maintenance and rapid delivery. Partnering with a seasoned tube filling machine supplier ensures that businesses receive tailored solutions that enhance efficiency and productivity.

The Role of Automatic Tube Filling Machines in Modern Industries

Automatic tube filling machines have become essential in modern industries due to their ability to streamline production processes. These machines offer significant advantages, such as increased speed, precision, and reduced labor costs. Operating at speeds of 10-30 units per minute, they efficiently handle tube diameters ranging from 13-50mm and heights from 80-200mm. The automation of processes like filling, sealing, and cutting not only boosts productivity but also minimizes human error. For industries looking to scale up production while maintaining high-quality standards, investing in technology from a reputable tube filling machine supplier is paramount. Automatic machines are a testament to the advancements in manufacturing technology, reflecting the industry's shift towards more sustainable and efficient production methods.

Comparing Tube Filling and Sealing Machine Options for Businesses

When selecting the right tube filling and sealing machine, businesses must consider various factors, including the type of tubes being used, production capacity, and specific industry requirements. A reliable tube filling and sealing machine supplier offers a range of options tailored to meet these diverse needs. Machines capable of handling both plastic and aluminum-plastic tubes provide versatility for manufacturers across different sectors. Additionally, features such as easy disassembly and cleaning, along with internal and external heating for enhanced sealing, are critical considerations. By comparing options from different tube filling machine manufacturers, businesses can identify machines that offer the best balance of functionality, efficiency, and cost-effectiveness. A strategic partnership with a trusted supplier ensures access to cutting-edge technology and ongoing support.

In summary, the future of manufacturing is inextricably linked to the advancements in tube filling and sealing machines. These machines are pivotal in enhancing production efficiency and product quality across various industries. By partnering with an experienced tube filling machine supplier, businesses can leverage state-of-the-art technology to streamline their operations and stay competitive in the market. Whether through innovations in design, the benefits of automation, or the strategic selection of machine options, the role of tube filling machines remains integral to the success of modern manufacturing. As industries continue to evolve, the demand for reliable tube filling machine manufacturers will only grow, underscoring their importance in the global supply chain.

Comments

Post a Comment