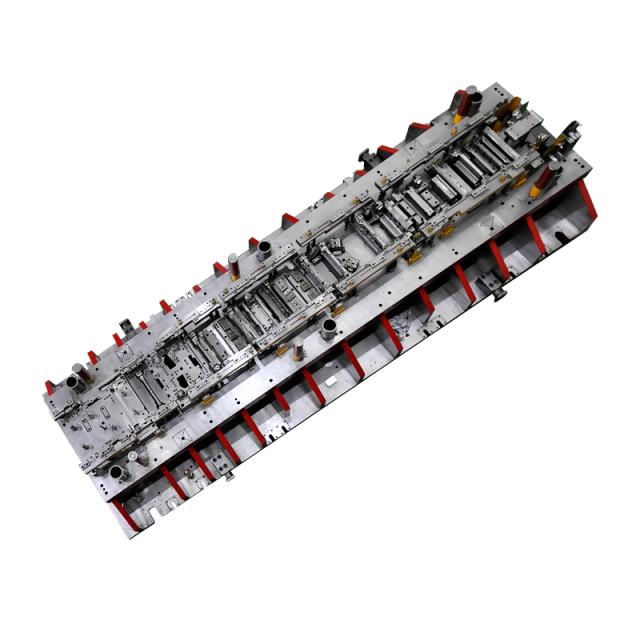

Automotive Stamping Dies Designed for Complex Mounting Components in Vehicle Assembly

Table of contents:

Tailored Die Solutions for Brackets and Reinforcements Meeting Tight Tolerances

Addressing High-Volume Manufacturing Requirements with Robust Die Structures

Quality and Repeatability Challenges in Progressive Stamping for Automotive Parts

Tailored Die Solutions for Brackets and Reinforcements Meeting Tight Tolerances

Robust solutions that meet tight tolerances are non-negotiable for automotive manufacturers, especially regarding brackets and reinforcements. Custom metal stamping dies play a crucial role in this regard, offering the flexibility and precision needed to create these complex shapes. ZYLY specializes in tailoring forming dies to match specific vehicle part geometries, ensuring that each component fits perfectly within the overall assembly. The use of optimized die structures, efficient material flow, and carefully planned stamping sequences minimizes deformation, resulting in components that adhere to tight tolerances. This meticulous approach allows manufacturers to achieve a smooth final assembly, reducing the risk of downstream issues. ZYLY's integrated production system ensures seamless coordination between die design and stamping, enhancing the stability of the entire process. By reducing trial-and-error and maintaining consistent quality, manufacturers can trust ZYLY to deliver reliable solutions for challenging automotive applications. The full customization of components supports the industry's demand for precision and efficiency, directly impacting production lines.

Addressing High-Volume Manufacturing Requirements with Robust Die Structures

Global expansion in the automotive industry has significantly increased high-volume manufacturing requirements, necessitating robust die structures. Custom metal stamping becomes increasingly essential when catering to large-scale production demands. ZYLY, a prominent metal stamping dies manufacturer, meets these needs with designs that withstand the rigors of high-volume use. Constructed from hardened tool steels featuring wear-resistant components, their forming dies endure constant pressure without dimensional drift. Regular maintenance and performance monitoring are employed to ensure the long-term durability of each die, offering manufacturers peace of mind even under repeated press conditions. This focus on durability translates directly to reliable, long-term production capabilities that align with large-scale industry standards. ZYLY's vertically integrated production facilitates streamlined coordination, enhancing batch-to-batch consistency and enabling quick adjustments based on real-time feedback. These robust die structures are the backbone of high-throughput stamping, offering critical support to manufacturers scaling up operations. With advanced capabilities supplied by a skilled metal stamping dies manufacturer, ZYLY drives efficiency and quality across automotive assembly lines.

Quality and Repeatability Challenges in Progressive Stamping for Automotive Parts

Ensuring quality and repeatability remains an ongoing challenge in the realm of automotive component production. Progressive stamping, a common method to manage these tasks, revolves around producing consistent parts efficiently. ZYLY excels in addressing this need as a key metal stamping dies manufacturer by offering custom metal stamping solutions specifically designed for repeatability. Their in-house capabilities in die design, manufacturing, and stamping create a cohesive system that aligns tooling geometry with press parameters and production processes. This holistic approach significantly reduces lead times and enhances batch-to-batch consistency. The detailed creative process helps mitigate any inconsistencies that might plague progressive stamping methods, ensuring that every component meets stringent industry standards. ZYLY's dedication to repeatable quality allows manufacturers to adapt quickly to new vehicle models or component changes, facilitating efficient pilot runs and flexible production scaling. By investing in custom metal stamping dies, manufacturers secure a streamlined production process that prioritizes both quality and efficiency, positioning themselves advantageously in a competitive market.

Manufacturers searching for reliability know that custom metal stamping is not merely beneficial but essential in producing top-tier automotive parts. ZYLY's forming dies address the critical aspects of shape control, dimensional consistency, and durability that automotive manufacturers value most. With over 15 years of experience entrenched in stamping die development, ZYLY continues to provide sophisticated solutions to the automotive industry and beyond. Their facility's capacity supports extensive manufacturing needs with presses ranging from 40 to 400 tons, and a remarkable monthly stamping throughput exceeding 500,000 parts. As automotive manufacturers seek dependable and high-quality custom metal stamping dies to maintain a competitive edge, ZYLY stands ready to embark on collaborative solutions that promise precision, efficiency, and ongoing innovation.

Comments

Post a Comment